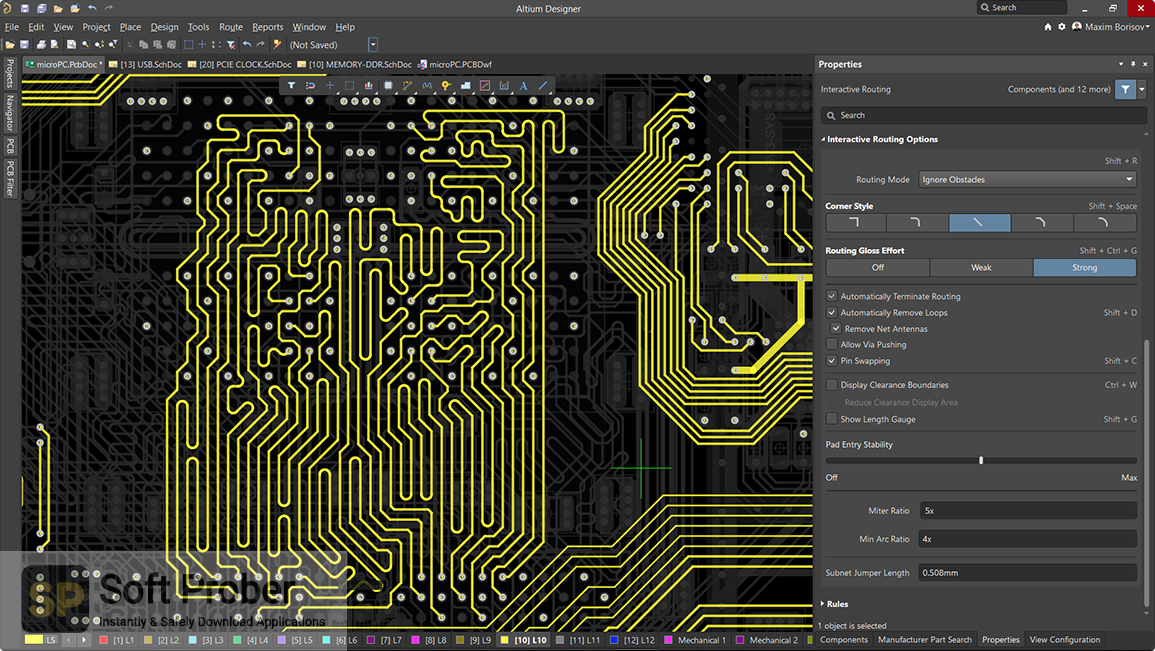

Your vias are what let you route between each layer in your board. Perhaps the most important routing features in a multilayer PCB are vias. Aspect ratios, board thickness, annular rings, and soldering can all be arranged beforehand in strong PCB design software.Ĭustomizing Drill Steps for Your Vias Is Easy With Altium Designer An integrated design package gives you the power to design top-quality printed circuit boards and define your manufacturing specifications within a unified environment. With all the design and routing features required to make your PCB work properly, it is understandable that folks tend to overlook fabrication and PCB manufacturing. Keeping your information clear, precise, and documented will keep your production process running forward. Altium Designer has all the tools you need to define your via structures and includes the fabrication and drill holes in your manufacturing outputs. You’ll need to define drilling steps for your vias, conductive and non-conductive fill options, any via tenting, and connections to other layers in the PCB stackup. Once you’ve placed your pads and vias, and you’ve defined your hole sizes, there is still more work to do. Take Control of Your Via and PCB Drill Size Specifications Your layout and fabrication specifications sync directly to your manufacturing outputs and are exported in standard file formats, including drill tables in your NC drill files and Gerbers. Generating your manufacturing outputs is easy in Altium Designer. Once you set your via size, Altium Designer gives you features to optimize your nets, verify trace clearance, and route between layers. The top-notch CAD tools in Altium designer let you build the best quality layouts with customized pad/via templates that are easily placed in your PCB layout. When you work with the best design software, it’s easy to define customized vias, tooling hole features, and drilling specifications that translate directly into your manufacturing outputs. These drill specifications are extremely important when you move to manufacturing your printed circuit board. Your tolerance allowance should never be smaller than 0.6mm for Level A, 0.5 mm for Level B, and 0.4 mm for Level C. The tolerance value will depend on the IPC Producibility Levels. Minimum Annular Ring on the Outer Layer: 0.05 mm Minimum Annular Ring on the Inner Layer: 0.1 mm Ring Border) * 2 + (Tolerance Allowance) + (Hole Size) The pad size needed to support a drill bit depends on the size of the annular ring placed around a hole, the hole size, and the tolerance: Pad Diameter Needed for Your PCB Drill BitsĪccording to the IPC-2221A Standard Specification, your drill bit size depends on the pad size, and vice versa, in order to ensure reliability and yield.

ALTIUM DESIGNER PCB LIBRARY SIZE SOFTWARE

The right PCB design software can help ensure your next design is manufactured correctly with the right PCB drill sizes.

Knowing something about the standard PCB drill sizes and how a drill hole is defined in your PCB design software will help ensure your fabrication run is successful and has high yield. Part of ensuring successful manufacturing involves placing the correct fabrication notes into your documentation, which should be pulled directly from your design data.Īn important part of PCB fabrication is placing drill holes with standard drill bit sizes in the board to provide through-hole component solder points, mounting holes, and via holes in your circuit board.

Your CAD software should help you stay productive in all of your design projects, and it should help you get your designs into manufacturing. With the number of PCB design software programs and utilities out there, it can be difficult to choose the program that will work best for you. A PCB design software package that generates manufacturing and assembly instructions in industry-standard file formats.

0 kommentar(er)

0 kommentar(er)